Panels for interior finishing on the basis of GThis is a material of new generation developed specially for the territories with severely continental climate and increased humidity. The material has two-side HPL covering, which gives decorative properties to a panel with finishing, and enables to exclude “wet processes” from the interior finishing of premises.

Combination of unique properties of GMS and HPL confer the following properties to the panels STENOPAN:

S (glass-and-magnesium sheet):

- Protection against vandalism, moisture resistance, ecological safety, fire safety (flammability class G1).

- Wall panels STENOPAN are resistant to chemical reagents, UV-radiation, they are wear and impact resistant, easy to clean, do not lose their properties under frequent action of water and detergents.

- Wall panels STENOPAN are used for interior finishing of medical and educational entities, office buildings, retail centers, lift cabins, as well as in all premises with high traffic and strict requirements for fire safety.

- Wall panels STENOPAN are offered with various patterns range – one-colored, imitation of wood, marble, and they may have different surface structure.

Sheet size: 1,220×2,440 mm.

Thickness of panels with both-side HPL: 10, 12 mm

The spheres of application

Public places

Accommodations

AccommodationsSport facilities

Industrial premises

Industrial premisesPartitions

The ceilings

Walls

Slopes for windows

Slopes for windows

Benefits of Stenopan panels

Hihg mechanic density

UV resistance

Easy installation

Resistance to moisture

Fire resistance

Resistance to temperature variable

from -60 С to +80 С

Resistance to chemicals

Sound and thermal insulation

Wide range of decor

Stenopan panels

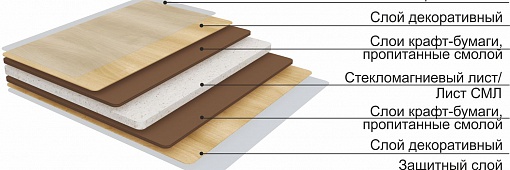

Stenopan - a wall panel made of glass-magnesite sheet , lined with high-pressure plastic (HPL), 0.8 mm thick.

Stenopan is a finished finishing material based on the main elements such as magnesium chloride and magnesium oxide (burnt magnesia). Also, “volcanic glass” is added to the LSU material to impart soundproofing properties to the material. At the next stage, plastic coated LSU is obtained - on both sides the LSU sheet is lined with HPL high-pressure plastic based on kraft paper, phenol-formaldehyde, amino-formaldehyde pitches and protective layers of overlay and underlay.