HPL Sloplast Biocidal - a decorative slow-burning plastic, the surface of which has special biocidal properties that prevent the spread of mold and fungi.

HPL Sloplast Biocidal is used in the construction industry as a finishing material in places with high traffic: residential, industrial, public buildings, food blocks, escalator balustrades, toilets (interior decoration and manufacture of sanitary partitions).

Also HPL Sloplast Biocidal is used for interior decoration of ships and land vehicles.

The coefficient of environmental cleanliness - 0.68

The degree of environmental safety - 2

The spheres of application

Public areas

Catering sections

Catering sections Sanitary partitions

Sanitary partitions Toilets

Toilets

Benefits of HPL panels

Hihg mechanic density

Easy installation

Resistance to moisture

Fire resistance

Resistance to temperature variable

from -60 С to +80 С

Resistance to chemicals

Wide range of decor

HPL Sloplast Biocidal

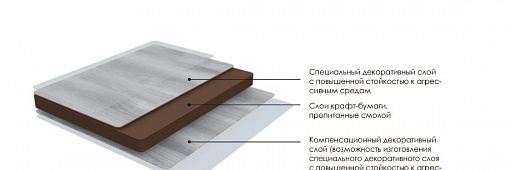

Decorative paper-based laminaDecorative paper-based laminate SLOPLAST is a high-pressure facing and structural plastic material, also called HPL (High Pressure Laminate), with a decorative surface suitable for external and internal works, resistant to mechanical impacts, light, it is weather insensitive. HPL consists of sheets of special kraftpaper impregnated with synthetic thermoreactive resins. Production technology envisages the combined treatment of paper under the effect of high temperature and pressure at special presses. Such treatment enables the resins to penetrate into the structure of paper, filling the fibers and changing its structure at chemical level. As a result, the uniform monolith material with unique operating performance characteristics is produced.

The thickness of the decorative plastic depends on the number of paper layers, it varies within the limits between 0.6 and 25 mm. Technology of material production enables to make various types of the surface finishing – glossy, matt, or textured; plastic sheets can be decorated from one side or from two sides.